Interior wooden doors are essential in contemporary architecture, providing both elegance and functionality to any environment. The demand for wooden doors, particularly custom wooden doors, has surged significantly, underscoring their popularity and versatility. Crafting an interior door involves intricate craftsmanship, with each custom wooden door displaying unique artistry and skill. A reputable wooden door supplier guarantees quality and precision in every product. The market for these doors is anticipated to reach $24.89 billion by 2031, emphasizing the enduring appeal of wooden doors in both residential and commercial settings.

Understanding the Basics of Wooden Door Manufacturing

Creating a wooden door involves understanding the materials and tools needed. Let’s dive into the essentials.

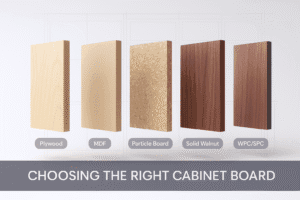

Types of Wood Used

Hardwood vs. Softwood

Choosing the right wood is crucial. Hardwood like oak or mahogany offers durability and strength. These woods resist wear and provide a classic look. Softwood, such as pine, is lighter and easier to work with. Softwoods often cost less, making them a popular choice for budget-friendly projects. Each type of wood brings unique qualities to a wooden door.

Sustainable Wood Options

Sustainability matters in today’s world. Opt for sustainable wood options to support eco-friendly practices. Look for certifications like FSC (Forest Stewardship Council) that ensure responsible sourcing. Sustainable wood helps reduce environmental impact while maintaining quality.

Tools and Equipment Required

Essential Machinery

Manufacturing wooden doors requires specific machinery. Essential machinery includes saws, planers, and sanders. These tools shape and smooth the wood. Veneering machines add decorative finishes. High-quality equipment ensures precision and efficiency in crafting each wooden door.

Safety Equipment

Safety should always come first. Use proper safety equipment like goggles, gloves, and ear protection. These items protect you from potential hazards. Maintaining a safe workspace ensures a smooth manufacturing process.

Understanding these basics sets the foundation for creating beautiful and functional wooden doors. Whether you choose hardwood or softwood or focus on sustainability, the right tools and materials make all the difference.

Designing the Interior Door

Designing an interior door involves creativity and precision. You can create a unique piece that fits your style and needs. Let’s explore how to design a custom solid wooden door.

Creating a Design Blueprint

A design blueprint serves as the roadmap for your interior door. You need accurate measurements and specifications to ensure a perfect fit.

Measurements and Specifications

Start by measuring the doorway where the interior door will hang. Use a tape measure to get the height, width, and depth. Write down these measurements. Accurate specifications prevent issues during installation. Double-check your numbers to avoid mistakes.

Design Software and Tools

Design software helps bring your vision to life. Programs like SketchUp or AutoCAD let you create detailed blueprints. These tools offer features to customize dimensions and styles. You can experiment with different designs before finalizing your choice. A digital blueprint guides the manufacturing process.

Customization Options for Custom Wooden Doors

Customization adds personality to your custom wooden doors (Painted Doors & Paint Free Doors). You can choose from various panel designs and decorative elements.

Panel Designs

Panel designs give your door character. Consider options like raised panels, flat panels, or glass inserts. Each style offers a different look and feel. Raised panels provide a classic appearance. Flat panels suit modern aesthetics. Glass inserts add elegance and light. Choose a design that complements your home decor.

Decorative Elements

Decorative elements enhance the beauty of custom wooden doors. Add features like carvings, moldings, or inlays. Carvings offer intricate details and craftsmanship. Moldings create depth and texture. Inlays introduce contrasting materials for visual interest. These elements transform a simple door into a work of art.

Designing an interior door allows you to express creativity and meet functional needs. Accurate measurements and thoughtful customization lead to a stunning result. Whether you prefer traditional or contemporary styles, the right design makes your custom wooden doors stand out.

Preparing the Wood for Interior Doors for Home

Selecting and Cutting the Wood

Choosing Quality Wood

Selecting the right wood sets the stage for a beautiful door. Hardwoods like oak or hickory shine in high-traffic areas. These woods offer durability and strength. For moisture resistance, consider teak or cedar. These options work well for environments with varying humidity. Always inspect the wood for knots or imperfections. Quality wood ensures a long-lasting door.

Cutting Techniques

Cutting wood requires precision and care. Use a sharp saw to make clean cuts. Measure twice before cutting to avoid mistakes. A straight edge helps guide the saw for accuracy. Cutting techniques impact the final look of the door. Practice makes perfect, so take your time.

Treating and Drying the Wood

Wood Treatment Methods

Treating wood protects it from pests and decay. Apply a wood preservative to extend the life of the door. Some treatments enhance the wood’s natural beauty. Choose a method that suits your needs. Treated wood stands up better to wear and tear.

Drying Processes

Drying wood is crucial for stability. Kiln drying controls temperature and humidity. This process prevents warping and cracking. Air drying takes longer but offers a natural finish. Properly dried wood maintains its shape over time. Drying processes ensure a solid foundation for your door.

Assembling the Wooden Door

Assembling a wooden door brings all the pieces together. This step requires precision and care to ensure everything fits perfectly.

Joining Techniques

Joining techniques hold the door parts securely. Two popular methods are mortise and tenon joints and dowel joints.

Mortise and Tenon Joints

Mortise and tenon joints provide strong connections. You cut a slot (mortise) into one piece of wood. Then, you shape a tongue (tenon) on another piece to fit snugly into the slot. This technique has been used for centuries due to its durability. You’ll find it in many high-quality doors.

Dowel Joints

Dowel joints offer a simpler alternative. You drill holes into the pieces you want to join. Then, you insert wooden dowels with glue to hold them together. Dowel joints are easy to align and assemble. They work well for those looking for a straightforward method.

Adding Hardware to Interior Doors

Hardware adds functionality and style to your door. Hinges, handles, and lock mechanisms play crucial roles.

Hinges and Handles

Hinges attach the door to the frame. You’ll need to choose the right size and type for your door. Handles come in various styles and finishes. You can pick ones that match your decor. Installing hinges and handles requires careful alignment to ensure smooth operation.

Lock Mechanisms

Lock mechanisms provide security. You can choose from simple latches to more complex locks. Make sure the lock aligns properly with the strike plate on the door frame. Proper installation ensures that the door closes securely.

Assembling your wooden door involves careful attention to detail. Choosing the right joining techniques and hardware makes a big difference. Enjoy the satisfaction of seeing your door come together beautifully.

Finishing the Custom Wooden Doors

Finishing a wooden door brings out its beauty and protects it. Let’s explore how you can achieve a perfect finish.

Sanding and Smoothing

Sanding and smoothing prepare the surface for finishing. This step ensures a flawless look.

Sanding Techniques

Start with coarse sandpaper to remove rough spots. Gradually move to finer grits for a smooth surface. Always sand in the direction of the wood grain. This technique prevents scratches and keeps the texture even. Use a sanding block for better control and even pressure.

Smoothing the Surface

After sanding, wipe the surface with a damp cloth. This removes dust and reveals any missed areas. Inspect the wood closely. Repeat sanding if necessary. A smooth surface ensures the finish adheres properly and looks professional.

Applying Finishes

Applying finishes enhances the wood’s appearance and offers protection. Choose the right finish for your needs.

Staining and Painting

Staining adds color while highlighting the wood grain. Choose a stain that complements your decor. Apply with a brush or cloth, following the grain. Allow it to dry completely. Painting provides a solid color and hides imperfections. Use a primer first for better adhesion.

Protective Coatings

Protective coatings shield the door from wear and tear. Options include varnish, enamel, or wax sealants. Varnish offers a glossy finish and strong protection. Enamel provides a durable, painted look. Wax sealants give a natural feel with a subtle shine. Choose based on the desired appearance and level of protection.

Finishing your custom wooden door requires patience and attention to detail. Proper sanding and the right finish transform a simple door into a masterpiece. Enjoy the satisfaction of a job well done!

Quality Control and Testing for Wooden Door Suppliers in China

Quality control ensures that every wooden door meets high standards. A reliable wooden door supplier focuses on quality to deliver durable products in China.

Inspecting the Finished Product

Inspecting each door guarantees top-notch quality. You need to check for defects and ensure durability.

Checking for Defects

Examine the door closely. Look for scratches, dents, or uneven surfaces. Use a checklist to cover all potential issues. Identifying defects early prevents future problems. A flawless finish enhances the door’s appeal.

Ensuring Durability

Test the door’s strength. Apply pressure to different areas. Ensure the door withstands daily use. Durability tests confirm the door’s long-lasting performance. Strong doors provide peace of mind.

Testing for Functionality

Functionality tests ensure the door works perfectly. Focus on door alignment and hardware functionality.

Door Alignment

Check if the door hangs straight. Open and close the door several times. Listen for unusual sounds. Proper alignment ensures smooth operation. Misaligned doors cause wear and tear.

Hardware Functionality

Test the hinges and handles. Make sure they move smoothly. Check the lock mechanism. Ensure it secures the door properly. Functional hardware adds convenience and safety.

A comprehensive quality control process leads to satisfied customers. A trusted wooden door supplier like WoodDoorSupplier uses rigorous standards. This approach guarantees durable and functional doors for any setting.

You’ve explored the fascinating journey of crafting interior wooden doors. The process involves selecting quality wood, designing with precision, and assembling with care. Each stage requires attention to detail and a commitment to excellence. Quality and craftsmanship are crucial for creating doors that stand the test of time. For those seeking reliable custom wooden doors, Wood Door Supplier stands out as a trusted partner at factory manufacturer wholesale pricing in China. The company values quality, reliability, and customer satisfaction. Trust Wood Door Supplier to deliver exceptional products that enhance any space.